The melting point of a substance is the temperature at which this phase change occurs. In general melting is a phase change of a substance from the solid to the liquid phase.

Metal Melting Point o C Admiralty Brass.

Melting point of high carbon steel. Carbon steel and stainless steel have the same basic ingredients of iron and carbon. Melting point of low-carbon steel is around 1450C. As reflected by the median melting points of low alloy steel which is 1436 OC 2610 OF and high allow steel which is 1415 OC 2600 OF.

We look at the different melting points. Carbon steel or plain-carbon steel is a metal alloy. We can assume that the same applies to all alloying elements mentioned above.

Melting point is the temperature at which a substance changes from solid to liquid state. Melting point of low-carbon steel is around 1450C. A metals melting point is the temperature that a metal begins to transform from a solid phase into a liquid phase.

In general melting is a phase change of a substance from the solid to the liquid phase. Melting points for some metals and alloys. No minimum content is specified or required for chromium cobalt molybdenum nickel niobium titanium tungsten vanadium zirconium or any other element to be added to obtain a desired alloying effect.

Melting Point of Steel vs Titanium. They are then held at 1010oC 1850oF for 20 to 45 minutes and air cooled air quenched. D2 steels should be preheated very slowly to 815oC 1500oF and then temperature can be increased to 1010oC 1850oF.

In general melting is a phase change of a substance from the solid to the liquid phase. Difference Between Carbon Steel and Stainless Steel. On its own pure iron Fe has a melting point of 1535 OC so alloying it decreases its melting range as explained above.

The melting point of a substance is the temperature at which this phase change occurs. When selecting a metal for a high temperature application several different temperature points need to be evaluated and one of the most critical temperatures to know is the melting. So as you can see high carbon is a relative term.

It is a combination of two elements iron and carbon. Melting point of high-carbon steel is around 1515C. Their main difference is alloy contentcarbon steel has under 105 percent alloy content while stainless steel must contain 105.

Any steel with a carbon content of 055 percent or higher or about one part in 180 is considered high-carbon steel. In general melting is a phase change of a substance from the solid to the liquid phase. Melting Point of Metals Alloys Metal Melting Point oC oF Admiralty Brass 900 940 1650 1720 Aluminum 660 1220 Aluminum Alloy 463 671 865 1240 Aluminum Bronz.

Carbon Boiling Point Boiling point of Carbon is 4527C. The melting point of a substance is the temperature at which this phase change occurs. The only other elements allowed in plain-carbon steel are.

Melting Point of Carbon Steel Melting point of low-carbon steel is around 1450C. Manganese 165 max silicon 060 max and copper 060 max. Melting point of low-carbon steel is around 1450C.

Melting point of Ti-6Al-4V Grade 5 titanium alloy is around 1660C. Pure iron Fe has a fixed melting point of 1535C chromium Cr 1890C and nickel Ni 1453C compared to a range of 1400-1450 C for type 304 stainless steel. Melting Point of Mild Steel vs Medium vs High-carbon Steel.

The definition of carbon steel from the American Iron and Steel Institute AISI states. Steel Pipes and Temperature Expansion - Temperature expansion of carbon steel pipes. The melting point of a.

In general melting is a phase change of a substance from the solid to the liquid phase. Carbon steel is a steel with carbon content from about 005 up to 38 by weight. Pushing this content past 2 percent makes the result extremely brittle and of limited use although this is how cast-iron products eg wood stoves cookware are made.

Other elements are present in quantities too small to affect its properties. The melting point of low carbon steel is 1410C 2570F. In carbon steels the higher carbon content lowers the melting point.

AISI 1095 carbon steel can be annealed at 899C 1650F followed by slowly cooling in the furnace. The melting point of a substance is the temperature at which this phase change occurs. This type is further classified into medium carbon steel high carbon steel and ultra-high carbon steel with melting temperatures ranging from 1425-1540C 2600-2800F.

Melting point of 41xx steel chromoly steel is around 1427C. Melting Point of Carbon Steel vs Alloy Steel.

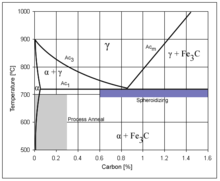

Classification Of Steel Powerpoint Slides

Classification Of Steel Powerpoint Slides

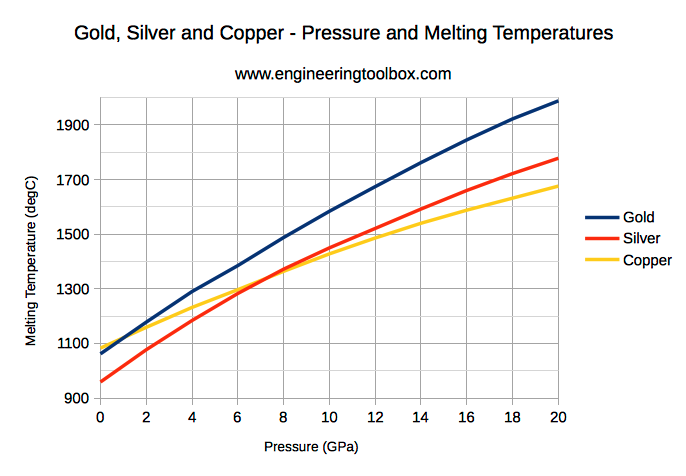

Metals And Alloys Melting Temperatures

Metals And Alloys Melting Temperatures

Classification Of Steel Powerpoint Slides

Classification Of Steel Powerpoint Slides

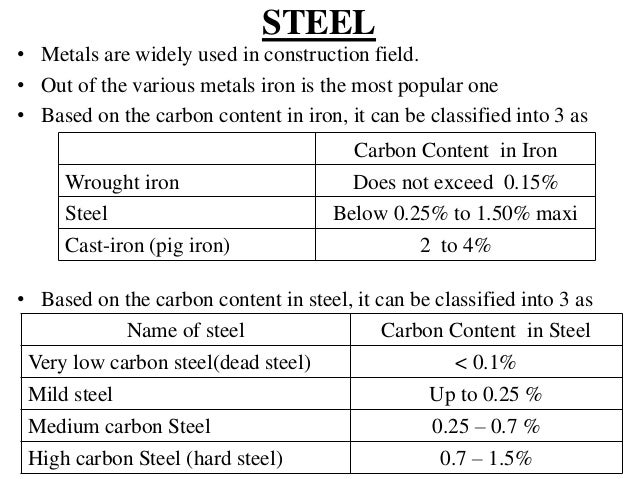

Carbon Content In Carbon Steel Classification Of Steel

Carbon Content In Carbon Steel Classification Of Steel

Carbon Content In Carbon Steel Classification Of Steel

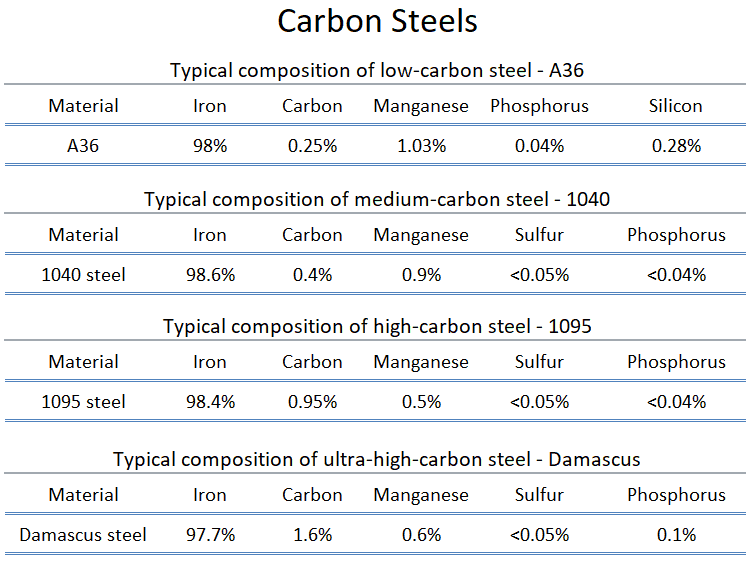

Carbon Steel Plain Carbon Steel Steels Properties Of Steels

Carbon Steel Plain Carbon Steel Steels Properties Of Steels

Carbon Steel Vs Alloy Steel Comparison Pros And Cons Material Properties

Carbon Steel Vs Alloy Steel Comparison Pros And Cons Material Properties

Melting Point Of Carbon Steel Stainless Steel General Technical Knowledge

Melting Point Of Carbon Steel Stainless Steel General Technical Knowledge

General Description And Weldability Of Ferrous Metals Welding Positions Welding Machines And Other Weliding Cutting Systems Plasma Welding

Difference Between Metal And Steel Definition Metal Properties

What Is The Difference Between Hss Metal And Carbon Steel Which One Has The Best Hardness Quora

What Is The Difference Between Hss Metal And Carbon Steel Which One Has The Best Hardness Quora